Ball bearings are used in a variety of dental instruments. In general, ball bearings are divided into two groups, depending on their speed of rotation. The speed is measured with RPM (revolutions per minute) – a measure which describes how many turns are completed in one minute around a fixed axis:

- Bearings with RMP from 100,000 to 500,000 are called HighSpeed bearings

- Bearings with RPM from 25,000 to 100,000 are called LowSpeed bearings.

The technical operation of a dental turbine is highly dependent on the choice of highspeed ball bearings. When selecting bearings, one has to be particularly sensitive to:

(1) the configuration of bearings,

(2) type of balls,

(3) the manufacturer.

(1) Configuration

Ball bearings are available in Angular contact configuration (Angular Contact Ball Bearings or ACBB) or in Radial contact configuration (Deep Groove Ball Bearings or DGBB).

The difference between the angular and radial bearings is in the retainer type which defines the support of load from axial and radial direction.

Angular contact ball bearings (fig. 1) better support “combined loads” (loading in both the radial and axial directions) because of a full retainer even though they can be axially loaded from one side only.

Radial ball bearings (fig. 2) include a crown retainer and because they can be axially loaded from either side are more convenient to use, but compared to angular contact ball bearings perform worse at higher speeds.

When it comes to a lifetime, on average angular contact ball bearings operate longer than radial bearings.

(2) Ceramic or Steel Balls

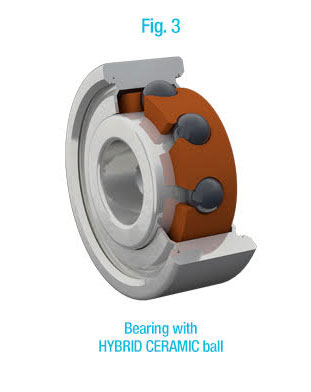

High speed ball-bearings are available with Hybrid Ceramic balls, which include hardened steel rings and silicon nitride (ceramic) balls, and with Steel balls, which have steel rings and steel balls.

The advantage of using a hybrid ceramic ball bearing (fig. 3) is that it runs cooler and extends bearing life. Ceramic balls are harder, smoother, lighter, and more wear resistant than stainless steel. They generate less bearing wear and lubricant degradation, produce lower internal bearing temperatures, and increase the bearing’s speed capabilities. Also, the ceramic bearing operates better than an all-steel ball bearing in low-lubrication conditions.

The benefits of Ceramic Angular contact bearings are:

- Longer lubricant service life

- Lower operating temperatures

- Increased speed rating

- Reduced weight

- No impact on assembly processes

- High stiffness

- Longer life

- Lower noise level (up to 25%)

(3) Manufacturer

When buying aftermarket dental turbines or dental bearings you have to pay attention on the bearing’s origin. There are many providers of dental bearings offering bearings of unknown origin. Those bearings mostly come from questionable productions or are produced for low standard markets. We strongly recommend you to ask providers of dental turbines which ball bearings do they assemble on turbines or sell.

We offer rotors assembled with top quality ball bearings, which are produced by Myonic, the producer of bearings for Original Equipment Manufacturers, like Kavo and W&H. Bearings can also be purchased as a stand-alone product.